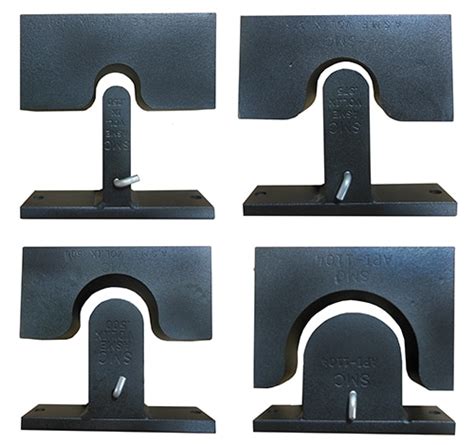

t-bend test|allowable defects bend : OEM This reliable T-Bend Test Equipment is engineered to assist with the professional evaluation of the coating performance of paint and coatings . Resultado da 23 de jul. de 2021 · Bastou que Billie Eilish passasse a mostrar um pouco mais de seu corpo publicamente, para que internautas começassem a .

{plog:ftitle_list}

Resultado da About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

The T-bend test is used to assess coating formability and adhesion. The highest rating, '0T', corresponds to a 180 • bend of the steel, resulting in the highest potential surface strain [42. Standard: AS 2728 (App F), NCCA II-19 The "T"-bend test is a very important test for ensuring the adhesion of the paint film during critical bending of the metal sheet.

This reliable T-Bend Test Equipment is engineered to assist with the professional evaluation of the coating performance of paint and coatings .The method can be used to confirm whether paints, varnishes or related products meet a given test requirement in a pass/fail test, or to determine the minimum bending diameter at which .A bend test is used to check the quality of different materials based on their properties. When selecting materials for a final product or prototype, you need to know if they will stand up to real-world use. Every material has a breaking . 1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the .

T-Bend Tester is designed to evaluate the flexibility and adhesion of an organic coating on a metallic substrate by observing the cracking or loss of adhesion when a coated test panel is bent. This method can be used to confirm .

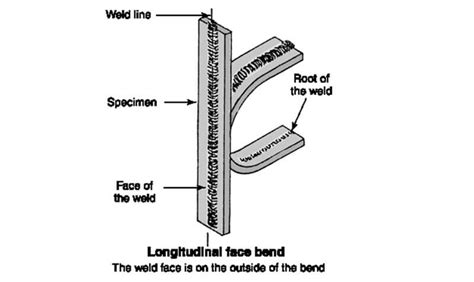

The dimensions for root bend test are given in ASME Section 9 QW-462.3 (a) is used to determine if the weld meets the requirements for this test. Face bend test. The transverse face bend test is a specimen loaded from the weld root side so that the weld face side become convex.

BGD 568---T-Bend Tester is designed to evaluate the flexibility and adhesion of an organic coating on a metallic substrate by observing the cracking or loss of adhesion when a coated test panel is bent.This method can be used to confirm whether paints, varnishes or related products meet a given test requirement in a pass/fail test, or to determine the minimum bending . Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and.The goal of ASTM D4145 is to assess the ability of a coating system to withstand strains of fabrication through the use of a T-bend test. In other words, this test characterizes the flexibility and adhesion of the coating after it had been subjected to a bending stress and it is through the use of the T-bend rating that it is possible to .

A semi-guided bend test, like the guided bend test, is often used to evaluate the quality of welds. However, in this test, the material isn’t constrained in a die assembly. Instead, it is bent freely over a rounded mandrel or a similar apparatus.to pass a 0T T-bend test despite determining that the applied strain in a 0T T-bend test was ~100%. Greunz et al. [ 11]used T-bend tests to study the adhesion properties of polyester-melamine coatings and found that the level of T-bend which a coating is able to pass is mainly affected by the surface treat-

T-Bend Tester is designed to evaluate the flexibility and adhesion of an organic coating on a metallic substrate by observing the cracking or loss of adhesion when a coated test panel is bent. This method can be used to confirm whether paints, varnishes or related products meet a given test requirement in a pass/fail test, or to determine the .

FREE-BEND TEST FOR WELD TESTING. Free Bend Test measures the ductility of the weld metal in a butt joint in a plate or pipe in terms of elongation percentage. The thickness of the specimen is the same as that of the plate or the pipe, the width is 1.5times the thickness and the length is anywhere between 150 mm for 6 mm t and 450 mm for 50 mm .The Model BT3 Bend Tester uses a unique method for wrapping the bend specimen around the mandrel. Specimens are forced to conform to the mandrel surface. This is especially useful for specimens from dissimilar metal weldments or those with significantly different weld and base metal strengths.

Coil Coated metals - Test Methods - Part 7: RESISTANCE TO CRACKING ON BENDING (T-bend test) Part 7 describes the procedure for determining the resistance to cracking of an organic coating on a metallic substrate when bent through 135° to . While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety .

A bend test is a method for measuring stiffness and yield properties of certain materials. Bend tests for ductility provide a simple way to evaluate the quality of materials by their ability to resist cracking or other surface irregularities during one continuous bend. In certain cases the bend test can determine tensile strength. Rest your leg in am elevated position. This will use gravity to help minimize the accumulation of swelling in the knee. Aim for 15-30 minutes per session, 3-5 times per day.. d) Keep The Leg Moving! General movements of .

weld guided bend test equipment

B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria. MTS Senior Application Engineer, Garrett Georgeson, demonstrates a 3-point bend test.Learn more about bend testing applications and common bend test standard.Scope: Precoated metal sheets can experience cracking and peeling of coatings, when subjected to rolling, bending or similar deformation during fabrication.The ASTM D4145 test evaluates flexibility and adhesiveness of organic coatings on precoated metallic sheets. The types of damage to coating evaluated by this test are cracking and loss of adhesion, caused by bend .Bend test. Buy. Follow. Table of contents. Foreword. 1 Scope. 2 Normative references. 3 Terms and definitions. 4 Symbols, designations and units. 5 Principle. 6 Test equipment. 6.1 General. 6.2 Bending device with supports and a former. 6.3 Bending device with a V-block. 6.4 Bending device with a clamp.

The types of bend tests discussed are bending ductility tests, bending strength tests (ASTM E 855), bend tests as per EN 12384 and JIS 3130, and computer-aided bending tests. The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test.A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials.This testing methodology involves subjecting a specimen to a controlled bending force to evaluate its resistance to deformation. The bend test is important in construction processes involving .flange section of the T, on the side opposite the stem of the T formed by the web section, and bent to produce a uniform transverse elongation across the surfaces of the fillet welds connecting the web and flange. This test is called a fillet weld keyhole T bend test because of its appearance. Its purpose is to fillIS:15!99-1985 Fro. 2 BEND TEST BY TSSE USE OF V-BLOCK Fro. 3 BEND TEST THROUGH AN ANGLE OVER A SPECIFIED RADIUS’ 4.2 Bending Device with Supports and a Mandrel 4.2.1 The length of the supports and the width of the mandrel shall be greater than the width or diameter of the test piece.

The bend test is a straightforward and low-cost qualitative method for determining a material's ductility and structural integrity. A mechanical test called bend testing is frequently used to evaluate a material's ductil ity and structural integrity, especially with regard to metals and alloys. This test provides important information about a material's capacity to sustain applied loads .EN 13523-7 - Paints and varnishes - T-bend test “Folding method” T-Bend Tester BGD 568 Mandrel and T-Bend Testers Solvica B.V. • P.O. Box 202 • 8250 AE • Dronten • The Netherlands • +31 (0)88 33 10 661 • [email protected] • www.solvica.com. Main Technical ParametersCaltech India offers CES 568 T-Bend Tester which is designed to evaluate the flexibility and adhesion of an organic coating on a metallic substrate by observing the cracking or loss of adhesion when a coated test panel is bent. This method can be used to confirm whether paints, varnishes or related products meet a given test requirement in a pass/fail test, or to determine .

paint film bending testing machine

bend-strength-test-machine

BATTLE IN STYLE with Free Fire, a free-to-play survival sho.

t-bend test|allowable defects bend